Air filtration products are mainly used in ventilation systems, such as air handling units for coarse filtration, second and third stage of filtering. EPA, HEPA and ULPA filters are included to catch also the smallest particle diameters at the desired efficiency. In the segment of industrial filtration, our product range offers filter cartridges and filter bags for gas and dust filtration in various industrial applications with the most demanding levels of clean environment.

CORSE AND FINE FILTRATION

The first and second stage of filtration in air handling units and ventilation systems. These filters are usually used as prefilters in a efficiency range from G2 and up to F9. Available in standard dimensions or non-standard dimensions with various frame designs.

- FILTER MEDIA

- PANEL FILTERS

- PREBAG FILTERS

ABSOLUTE FILTRATION (EPA, HEPA, ULPA)

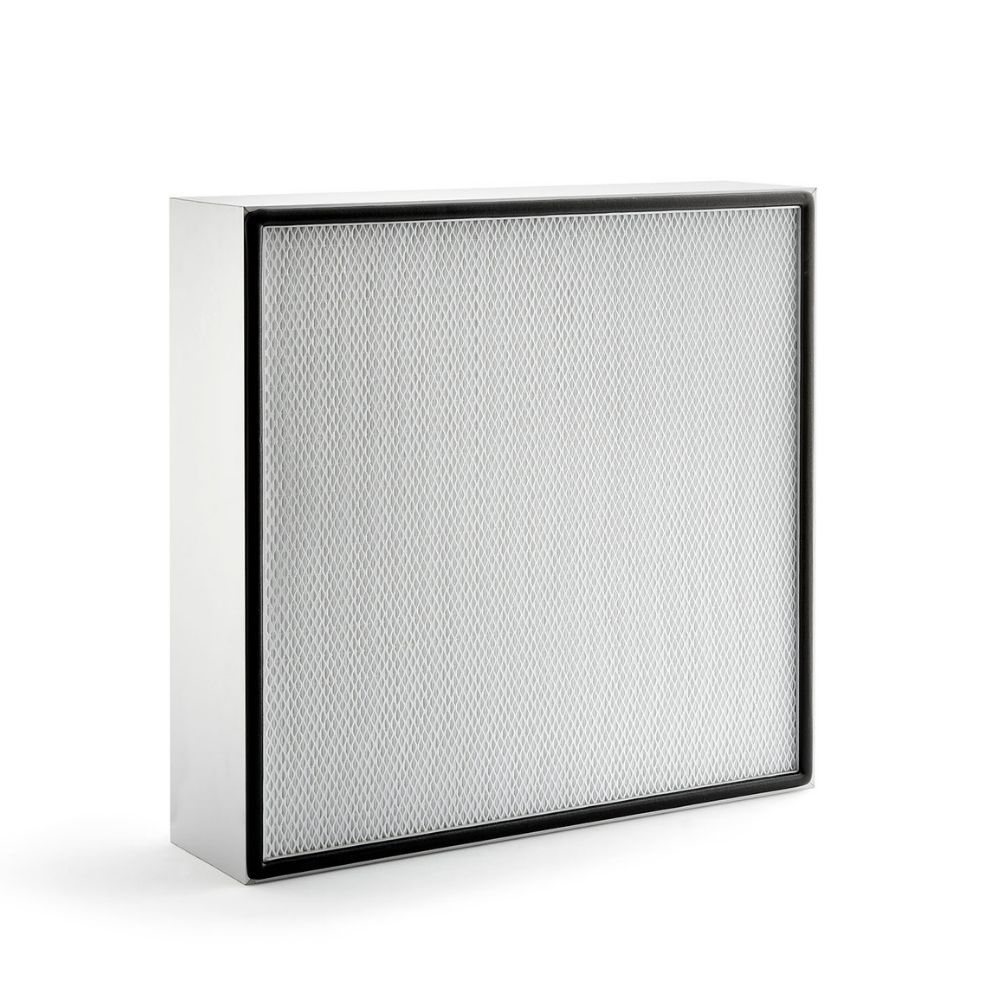

Used in working environments where high levels of air purity is required, such as clean rooms. Usually used in the third or last stage of the air filtering process to ensure atmosphere control. Manufactured with MDF, galvanized steel or aluminium frame and with different types of gaskets, such as half round polyurethane, EPDM and gel gasket. The used filter media is glass fiber paper folded in minipleat packs with efficiency levels that range from M6 to U18.

- COMPACT FILTERS

- HEPA FILTERS

- HIGH CAPACITY FILTERS

FILTER BAGS FOR GAS AND DUST FILTRATION

Industrial filter bags made from needle felt or fabrics made of synthetic fibers with the purpose of dust removal. Depending on the customers needs and application DELTA FILTER offers a wide range of filter media for industrial filter bags made from different types of fibers, to ensure a long lifetime of the filter bags and optimal results.

To ensure the best solution for our customers, we choose the right type of media, special protective and surface treatments for their application. Different fiber types and finishes are used for the bags, depending on the process conditions and granulometry of the filtered product to improve the filtration efficiency by increasing the useful life of the product:

- Glazed

- Coatings

- PTFE membrane

- Antistatic

We make the final design of the filter bags as requested or per sample in the available types, such as standard filter bags, filter sleeves, flat bags, channel bags with sewn rings, ATEX filter bags, etc.

List of available filter materials and fields of application:

Scrim and Fiber Type | Operating Temp. (Max.) | Fields of Application |

|---|---|---|

Polypropylene (PP) | 90°C | Chemical and Pharmaceutical Industry, Food Industry, Galvanizing, Plastic Production, Wood Processing |

Polyamide (PA) | 110°C | Wet Filtration |

Polyacrylonitrile homopolymer (DT) | 125°C | Coal Grinding Drying, Spray Dryer, Power Plants |

Polyester (PE) | 150°C | Cement Industry, Ceramic Industry, Food Industry, Metal Production, Mining, Plastic Production, Wood Processing |

Polyphenylensulfide (PPS) | 190°C | Cement Industry, Metal Production, Power Plants, Waste Incineration |

Meta aramide (NO, NX) | 200°C | Asphalt Mixing Plants, Ceramic Industry, Chemical Industry, Lime Industry, Metal Production |

Polyimide (PI) | 240°C | Cement Industry, Chemical Industry, Metal Production, Power Plants, Waste Incineration |

Polytetrafluorethylene (PTFE, TF, TFL) | 250°C | Carbon Black Industry, Chemical Industry, Power Plants, Waste Incineration |